- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-03 Origin: Site

Release paper stops sticky things from sticking. This makes it easy to peel off labels and adhesives. You can do this without making a mess. - Picking the right release paper makes products better and more even. It helps you not make mistakes when making things. - High-performance release paper is strong and does not break. It stays the same shape during fast work. - Some release paper is eco-friendly. This helps cut down on pollution and keeps the earth safe. - You can change release paper features like thickness and texture. This helps you get the best fit for your needs.

You might ask what release paper is and why it is important. Release paper, also called release liner, is a special paper or film. Makers cover it with a release agent, like silicone. This stops adhesives from sticking to the surface. The non-stick paper lets you work with sticky things without mess or damage. Release paper is used in many factories, like for stickers and synthetic leather. Its main job is to be a barrier. It keeps glue and sticky stuff from sticking where you do not want. Using release paper helps you pull things apart cleanly every time.

There are many kinds of release paper. Some have smooth surfaces, and some are rough. Some types keep out water better or work with certain chemicals. These choices help you pick the best release paper for your job.

Note: People around the world now want high-performance release paper for special jobs. Many companies need release paper made just for them.

Release paper does many important things in factories. You use it for:

Isolation performance: Release paper keeps glue from sticking during storage and shipping.

Physical performance: It stays strong and does not break on fast machines.

Chemical performance: Release paper works with many chemicals and avoids bad reactions.

You see release paper in cars, shoes, and electronics. High-performance release paper lasts longer and gives steady results. Picking the right kind of release paper makes your work and products better.

You should care about the environment too. Making and throwing away release paper can hurt air, water, and soil. Some release paper uses chemicals that are bad for nature. Choosing eco-friendly release paper helps stop pollution and keeps the planet healthy.

Release paper stops sticky stuff from staying on its surface. Silicone release paper has great non-stick features. You do not need much force to pull things apart. There is no leftover sticky mess. Silicone release agents help you remove items easily. This is important when you use adhesives or work with heat. You get cleaner results and save time in your factory. Non-stick paper works better than other materials. It is best when you need a clean release in hard jobs.

Tip: Strong non-stick release paper helps you avoid messes. It keeps your products neat and professional.

Release paper needs to be strong and stable. It should not tear or stretch during fast work. Dimensional stability is very important. If release paper changes shape, you may have problems. Printing can go wrong, or lamination can get wrinkles. Adhesive might spread where you do not want it. Good release paper uses special fibers and sizing agents. These help the paper keep its shape. You get steady results even when machines run fast.

Dimensional stability helps you avoid:

Printing mistakes

Wrinkles and bubbles

Adhesive leaks

Web breaks

You can pick release paper with the right thickness and strength. Customizing these features gives you more control in your factory.

Factories use lots of chemicals and high heat. Release paper must stand up to these things. You want paper that does not break down with chemicals like urea or zinc chloride. Some release papers pass tests like ASTM D543. This means they work well in tough places. Release paper also needs to work in heat press and heat transfer jobs. Special coatings help release paper stay strong in high heat.

Chemical | LDPE/HDPE Resistance |

|---|---|

Turpentine oil | Shows some effect after 7 days; immediate damage (not recommended) |

Urea | Little or no damage after 30 days |

Xylene | Immediate damage (not recommended) for LDPE; some effect after 7 days for HDPE |

Zinc chloride | Little or no damage after 30 days |

You can ask for release paper with special coatings. This lets you use release paper in many factory jobs.

The surface of release paper matters for your products. A smooth surface helps stop rust and keeps dirt away. You get better sealing and a nicer look. In stickers, smooth release paper helps you put on adhesive evenly. Stickers peel off easily. Users like this better.

Smoother surfaces make products last longer.

You see fewer mistakes in your products.

Consistent release force makes work easier.

You can change the surface of your release paper. Some jobs need very smooth paper. Others need rough paper. You can also pick colors and patterns for your brand.

Note: Modern release paper gives you many choices. You can pick thickness, smoothness, coating types, and colors. This helps you match release paper to your job and needs.

Customization Aspect | Description |

|---|---|

Thickness | Ask for the thickness you need. |

Surface Smoothness | Pick smooth or rough texture for your job. |

Coating Types | Choose coatings that resist heat or chemicals. |

Color Options | Pick colors for your brand or style. |

Release paper technology keeps getting better. You see new choices like biodegradable and recyclable release base paper. Advanced coatings and digital printing help you get better results and follow safety rules. You can use recycled release paper to save money and help the planet.

Release paper is used in many industries. It helps companies solve different problems in making products. Here are some common industries that use release paper:

Labels: This is the main area for release paper. E-commerce and consumer goods make this grow fast.

Food and Beverages: Release paper helps with labels. It makes brands easy to see.

Pharmaceuticals: There are strict rules for labels. Release paper is important here.

Logistics: Fast and correct packaging needs good release paper.

Release paper helps other important areas too. In footwear, special release paper bonds materials in sports shoes. In cars, release paper helps with adhesives when building electronic parts. Electronics factories use release paper to keep assembly lines working well.

Industry | Application Description |

|---|---|

Footwear | Special release paper is used in sports shoes. It helps materials stick together and work well. |

Automotive | Release paper helps put adhesive materials in electronic parts. |

Electronics | Release paper helps with assembly. It makes work faster and better. |

Release paper is also used in textiles and packaging. These uses show why release paper is important for modern factories.

Release paper gives many benefits in making things. It helps you work smoother and make better products. In packaging and textiles, release paper improves how coated fabrics feel and look. Release paper acts like a mold. It gives products the right texture. You can use release paper more than once. This saves money.

Release paper stops materials from sticking together. This means you do not get jams or slowdowns. In making composite materials, release paper helps add new layers easily.

Release paper keeps products safe from dirt and dust. It makes a barrier so nothing gets in. This means your products are cleaner and have fewer mistakes.

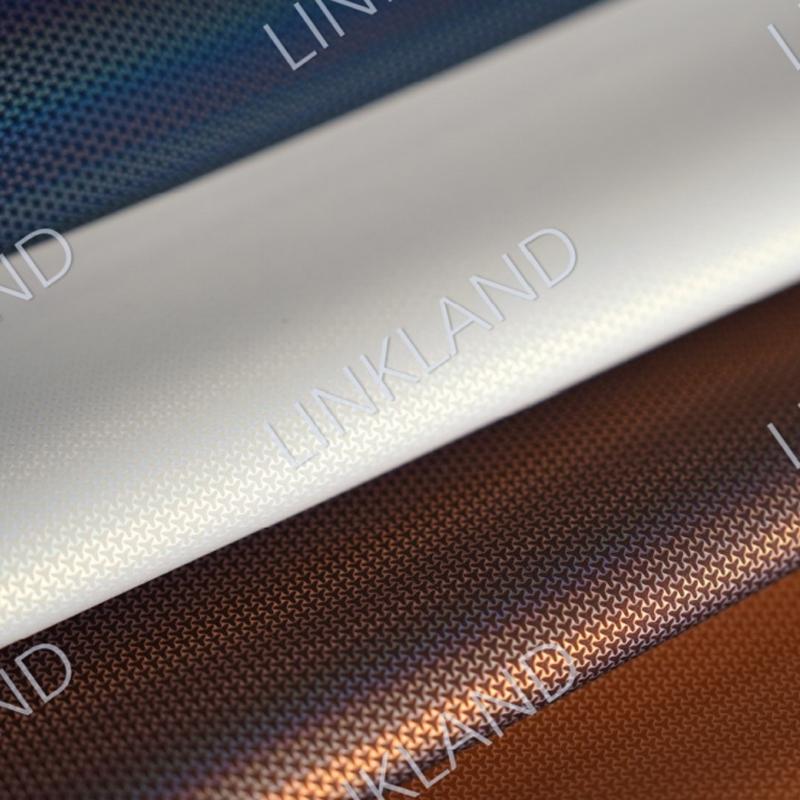

The LK-RW839J is a good example of release paper with many uses. You can use it in shoes, car interiors, textiles, and packaging. You can pick the weight, thickness, and color. This lets you get the right release paper for your job.

Tip: When you choose the best release paper for your job, you work faster and your products look better.

Release paper helps many industries. You see it in shoes, electronics, and more. It helps you work smarter and faster.

When you pick release paper, think about your job. First, know what you need the release paper to do. Look at your process and what you make. Check what kind of adhesive you use. Think about the surface you work with. Know how hot or cold your process gets. Pick release paper that fits your needs.

Find out what your job needs.

Look at the adhesive and the surface.

Know the temperature for your process.

Choose the release properties you want.

You also need to pick the right base material. Paper substrates are flexible and cost less. Film substrates, like polyethylene or polyester, are strong and keep out water. If you need something tough, use film substrates. Paper substrates are good if you do not need much water resistance.

It is important that the adhesive works with the release paper. Silicone release agents help stop sticking problems. You want the release paper to work well with your adhesive. If you use the wrong release agent, the liner may not come off easily.

You can also change the weight and thickness of your release paper. These choices affect how strong and tough it is. Thicker release paper is stronger. You can pick how easy it is to peel off the liner. If the coating is even, your machines work better.

Tip: Always match the release paper to your machine speed and liner thickness. This helps you avoid problems when cutting or working fast.

You need to make sure the release paper fits your job. Think about how it will work in your factory. For example, check if chemicals move from your product to the package. This keeps your product safe and stable.

Aspect | Description |

|---|---|

Purpose | Check if chemicals move between product and package. |

Importance | Keeps your product safe and stable on the shelf. |

When to Perform | Do this for new products, new packages, or changes in your process. |

Specific Requirements | Needed for aerosol packages because of leaks and other risks. |

You should also think about how long the release paper will last. It must stay strong through your whole process. If you work in wet places, you need moisture resistance. Silicone release agents help protect and add non-stick features.

To get the best results, pick release paper with the right features. Choose the thickness, release force, and coating that fit your job. You can also ask for special colors or patterns for your brand. Customizing helps you get the most from your release paper.

Release paper helps you work faster and keeps things clean. When you pick the right release paper, your products last longer and stay safe. You also make fewer mistakes and keep your products protected.

You now know that high-performance release paper helps factories today. It has non-stick, strong, and water-resistant features. These help you get clean results and make products last longer. When you pick the right release paper for your job, you get many good things:

You do not spend money on things you do not need.

Your products stay the same and work well every time.

People like your products more and need less help.

Pick the best release agent and change your release paper as needed. This gives you the best results in your factory work.