- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

Choosing the right shoes leather is a crucial step for any footwear manufacturer or designer. The material you select not only impacts the look and feel of the shoe but also influences durability, comfort, production cost, and ultimately customer satisfaction. With various options available—ranging from genuine leather to synthetic alternatives such as PU and PVC—making an informed decision can be challenging. Understanding the key performance factors and material characteristics is essential to ensure the final product meets both market demands and functional requirements.

When selecting the right shoes leather for your footwear production, several critical performance indicators must be evaluated to ensure the material meets both manufacturing and end-user needs.

Thickness

Thickness directly affects the sturdiness and flexibility of the shoe upper. A leather that is too thick may be rigid and uncomfortable, while one that is too thin could lack durability and structure. The LKL2406 offers a well-balanced thickness of 1.0mm, which provides sufficient strength to support the shoe’s form and withstand daily wear, while maintaining enough flexibility to contour comfortably to the wearer’s foot.

Width

The width of the leather roll is an important factor in production efficiency. A wider roll allows manufacturers to cut larger panels with fewer seams, reducing waste and labor costs. With a generous width of 137cm, LKL2406 is designed to optimize fabric utilization, making it highly suitable for large-scale shoe manufacturing processes.

Durability

Durability is essential for footwear materials that face constant abrasion, bending, and exposure to environmental factors like moisture and dirt. The composite PU/PVC coating on LKL2406 provides excellent resistance to scuffs and scratches, enhancing the shoe’s lifespan. Its water-repellent qualities also protect the shoe from damage caused by moisture, making it ideal for both casual and sports footwear.

Flexibility

Flexibility influences the comfort and mobility of the shoe. A leather material that lacks pliability can restrict movement and cause discomfort to the wearer. Thanks to its composite structure, LKL2406 maintains excellent flexibility without compromising strength, ensuring ease of movement and comfortable fit throughout daily activities.

The LKL2406 PU/PVC leather is specially engineered to meet the demanding requirements of modern shoe manufacturing, offering an excellent balance between functionality and style.

Composite Coating for Strength and Softness

This material combines polyurethane (PU) and polyvinyl chloride (PVC) coatings applied over a durable fabric base. The result is a leather that is simultaneously soft to the touch yet tough enough to withstand daily wear and tear, making it ideal for shoe uppers that require both comfort and longevity.

Optimal Thickness for Performance

At 1.0mm thickness, LKL2406 provides sufficient body to maintain shoe structure without compromising flexibility. This ensures that the footwear remains lightweight and comfortable, allowing natural foot movement without added bulk or stiffness.

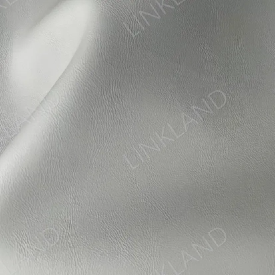

Natural Grain Surface Finish

The leather’s surface mimics the authentic grain of genuine leather, giving the shoe an upscale, premium appearance. Unlike real leather, it is easier to clean and maintain, reducing the effort and cost associated with upkeep while preserving an elegant look.

Water-Resistant Properties

LKL2406’s water repellency protects the footwear from moisture damage, which is crucial for extending the shoe’s usable life, especially in wet or humid conditions.

Customization for Market Trends

Available in a wide range of colors and patterns, this material provides manufacturers and designers with creative flexibility to produce fashionable and unique shoe designs that resonate with current consumer trends.

Overall, LKL2406 effectively balances durability, comfort, appearance, and cost-efficiency, making it a perfect fit for the footwear industry’s diverse needs.

Different shoe types require specific leather characteristics to optimize performance and consumer appeal. Here’s how LKL2406 fits into various footwear categories:

Casual Shoes: For everyday wear, lightweight and comfortable shoes benefit from LKL2406’s softness and breathability. It provides the perfect blend of style and practicality, appealing to consumers seeking affordable quality.

Athletic Shoes: Sports footwear demands materials that can withstand dynamic movements and moisture exposure. LKL2406’s abrasion resistance and moderate breathability make it ideal for running shoes, trainers, and other athletic models.

Boots: Boots often face harsh environmental conditions and need sturdy, water-resistant materials. The toughness and moisture protection of LKL2406 help maintain boot integrity and aesthetics in rugged or fashion-forward designs.

Fashion Footwear: Designers require materials that offer customization and high-end looks. LKL2406’s variety of colors and textures supports creative expression while maintaining ease of care, perfect for trend-driven markets.

One of the standout advantages of PU/PVC composite leather like LKL2406 is its exceptional adaptability for customization, offering far greater flexibility than genuine leather.

Quickly Align with Trends

Because synthetic leathers can be produced in a wide spectrum of colors and patterns, footwear brands can rapidly respond to seasonal fashion trends and evolving consumer preferences, keeping their product lines fresh and relevant.

Unique and Limited-Edition Collections

Manufacturers can create exclusive designs with bold or subtle textures, helping brands differentiate themselves in a competitive marketplace by offering limited-edition or standout collections.

Consistent Quality and Color Accuracy

Unlike natural leather, synthetic materials allow for precise control over color consistency, ensuring uniformity across large production batches and multiple product lines.

Versatile Finishes

LKL2406 supports a variety of finishes—from matte and glossy to embossed patterns—providing designers with creative freedom to explore diverse aesthetics without sacrificing durability or performance.

This level of customization empowers brands to innovate quickly and effectively, meeting consumer demands while maintaining high material quality.

Choosing PU/PVC composite leather also brings economic and environmental advantages:

Cost Efficiency: Compared to genuine leather, PU/PVC materials are typically more affordable, allowing manufacturers to reduce costs while maintaining high product standards.

Production Consistency: Synthetic materials provide predictable quality and uniformity, reducing waste and defects in production.

Eco-Friendly Aspects: Modern PU/PVC leathers, including products like LKL2406, increasingly incorporate sustainable practices such as recyclable base fabrics and less harmful chemicals. Additionally, they avoid the ethical issues linked to animal leather.

Maintenance: PU/PVC leathers are easier to clean and require less upkeep than natural leather, making the footwear more user-friendly and extending its usable life.

These factors contribute to both lowering manufacturing expenses and appealing to environmentally conscious consumers.

Selecting the right shoes leather is a decisive factor in footwear success. Materials like the LKL2406 PU/PVC composite leather offer a comprehensive solution that meets the diverse needs of the footwear industry—combining durability, comfort, aesthetic versatility, and sustainability.

By incorporating premium synthetic leathers, brands can not only improve product performance and consumer satisfaction but also optimize production efficiency and cost. The customizable nature of LKL2406 empowers designers to craft innovative footwear collections that resonate with today’s market trends.

For footwear manufacturers seeking to elevate their product lines with high-quality, reliable materials, LKL2406 represents an excellent choice that balances quality with value.

Explore the possibilities with Taizhou Saiweiyue Mould & Plastic Co., Ltd. and their range of premium shoes leather. Visit www.linklandleather.com to learn more and request free samples to experience firsthand the benefits this material can bring to your footwear production.